How sustainable manufacturing keeps Western Europe competitive

As global competition intensifies, Western Europe faces the challenge of maintaining a strong manufacturing industry while reducing environmental impact. Countries in South America, Eastern Europe, and Asia often have lower labor costs, making it difficult for European manufacturers to compete on price alone. However, by focusing on sustainable manufacturing, we can stay ahead by leveraging efficiency, automation, and smart production strategies.

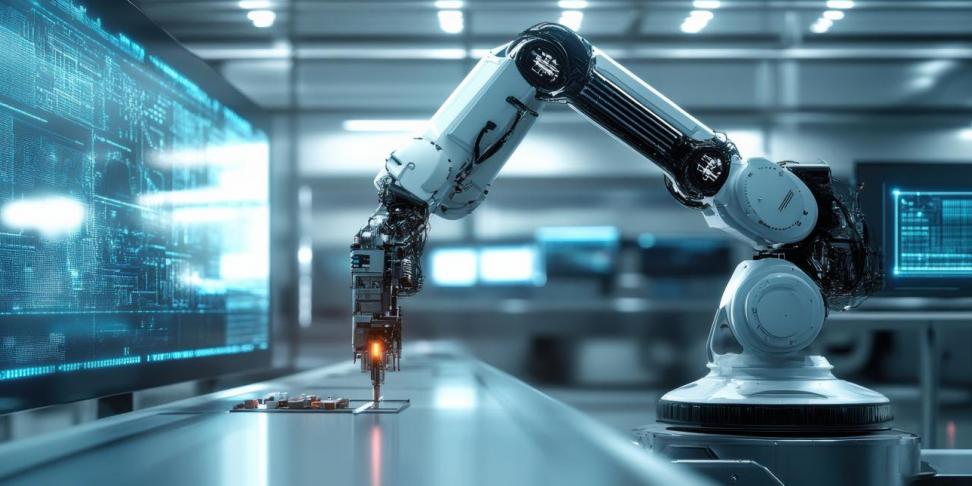

Rather than relying on cheap labor, Western Europe must embrace innovation. Smart manufacturing and industrial automation help manufacturers increase efficiency, optimize production, and reduce costs without sacrificing quality. Green manufacturing not only improves competitiveness but also aligns with stricter environmental regulations and growing consumer demand for sustainable products.

The role of smart manufacturing in reducing the carbon footprint

To remain competitive, manufacturers must optimize processes and minimize waste. Smart manufacturing integrates automation, robotics, and real-time data analysis to reduce the carbon footprint in manufacturing. By automating production lines, companies can lower energy consumption, optimize material usage, and improve overall efficiency.

For example, automated inspection systems help ensure product quality while minimizing material waste, and industrial machine vision improves defect detection, reducing unnecessary rework. These solutions enhance both sustainable production and cost savings by making manufacturing processes more precise and reliable.

Local for local: a key to sustainable manufacturing

One of the most effective ways to implement sustainable production is by shortening supply chains. Many manufacturers rely on international suppliers, which increases emissions due to long-distance transportation. A Local for Local approach—sourcing materials from nearby suppliers—helps companies:

- Reduce transportation-related CO₂ emissions.

- Improve supply chain resilience, avoiding disruptions from global logistics issues.

- Strengthen relationships with local suppliers, supporting economic stability.

Companies integrating local sourcing into their industrial automation strategies benefit from greater flexibility, improved cost control, and a lower environmental footprint. This approach complements advancements in automated production lines, which further streamline processes and enhance efficiency.

For manufacturers looking to improve cost-efficiency while embracing sustainability, Cost reduction in manufacturing explores additional strategies to lower operational expenses without compromising quality.

Green manufacturing beyond carbon reduction

While reducing emissions is a major aspect of green manufacturing, sustainability also involves energy efficiency, circular economy practices, and waste reduction.

- Energy-efficient production lines, powered by factory automation and CNC automation, minimize resource consumption and ensure that processes run optimally.

- Smart recycling technologies, integrated into automated production processes, help reuse materials and reduce waste.

- Sustainable materials and production methods ensure a longer product lifecycle, reducing overall environmental impact.

Companies adopting these strategies meet sustainability goals while also improving productivity. Smart manufacturing not only drives efficiency but also ensures long-term business viability.

The future of sustainable manufacturing in Western Europe

Manufacturers that embrace sustainable production and automation will have a significant advantage over competitors that rely solely on low-cost labor. Robotic assembly lines and robot welding automation improve production efficiency and consistency, allowing manufacturers to scale operations while maintaining environmental responsibility.

By leveraging automated inspection systems, vision technology, and industrial automation, manufacturers can build smarter, greener factories that align with both economic and environmental priorities. The future of manufacturing in Western Europe depends on balancing cost-efficiency with sustainability.

Is your manufacturing process future-proof?

VDL Steelweld helps companies integrate smart manufacturing and industrial automation solutions to improve efficiency, reduce costs, and minimize environmental impact. Learn more about our factory automation solutions and discover how we can help optimize your sustainable production strategy for a greener future.