Contract Manufacturing

Our Contract Manufacturing division specialises in a wide range of industries, including but not limited to:

- Manufacturing enabling, prototyping and small series: from the finished concept to the first prototype and the first series, all can be managed from one location and with one team.

- Series production: For series production, the setup can vary to only build-up the line for the commissioning and initial production ramp-up phase and to relocate it to the definitive location after this has been completed. Or the continued production of a product for a certain amount of years.

- Custom Projects: Have a unique product or manufacturing request? Our team likes to be challenged to take on custom manufacturing requests

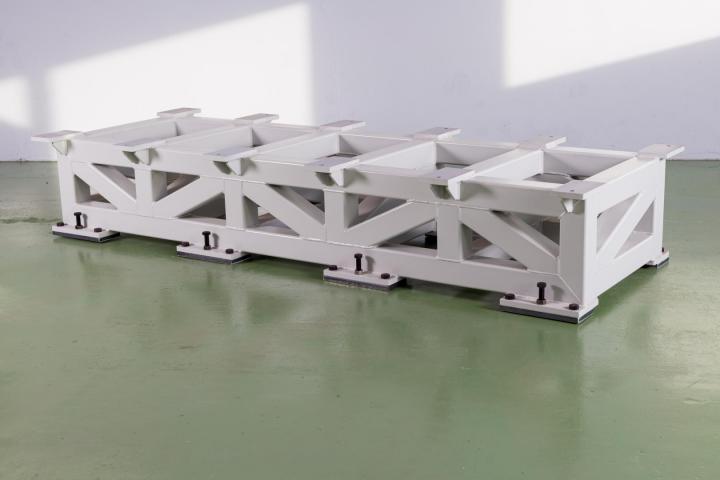

Welding & Machining

Assembly of Sub Systems

System Assembly

Our Contract Manufacturing division

differentiates itself by,

Quality Assurance

We adhere to the highest industry standards and employ detailed quality control processes to ensure the products we manufacture meet or exceed your expectations.

Manufacturing Innovation

Our team of engineers and experts is at the forefront of technological advancements. In the Production Line Solutions Division we are always working on new products, lines, technologies and concepts. Tapping into that innovativeness, we continuously invest in the latest manufacturing technologies to improve efficiency and enhance product quality. Enabling us to be the No. 1 in Contract Manufacturing.

Custom Solutions

We understand that one size does not fit all. Our flexible approach allows us to customise our services to match your unique requirements. Even if the product is not fully mature, we have engineering capabilities to also participate in a manufacturing enabling exercise; to match your product with an intended manufacturing process.

Collaborate with us

We invite you to explore the possibilities of collaborating with VDL Steelweld's Contract Manufacturing division. Our commitment to excellence, transparency, and outstanding customer service is our promise to you.