How virtual factories help manufacturers master complexity and reduce risk

Ask any manufacturing engineer what keeps them up at night, and the answer is rarely “automation.” It’s risk.

The risk of a new line not performing as expected. The risk of rework after months of engineering. The risk of losing time you don’t have. And budget you’ll never get back.

Most factories are still designed the old way: through assumptions, spreadsheets, and late-stage surprises. But complexity has outgrown that approach. The systems we build today -multi-robot, multi-product, multi-variant- are simply too interdependent to “wing it.”

You can’t manage that complexity by intuition anymore. That’s why the most forward-thinking engineers are turning to virtual factories.

The reality check: why “good enough” doesn’t cut it anymore.

Let’s be honest: most production lines work. Eventually. But at what cost?

Every new line launch comes with the same pattern:

-

Design looks perfect on paper.

-

Integration starts, and real-world deviations appear.

-

Software needs adjustment. Robots collide. Layout tweaks ripple through the project.

-

Deadlines stretch, commissioning overruns, and everyone’s weekend disappears.

The cost isn’t just financial. It’s reputational. When your customer sees you struggle to ramp up, they question your process maturity. And in today’s market where OEMs expect first-time-right delivery, and regulatory audits get tougher “good enough” has become a liability.

What a virtual factory really is (and isn’t)

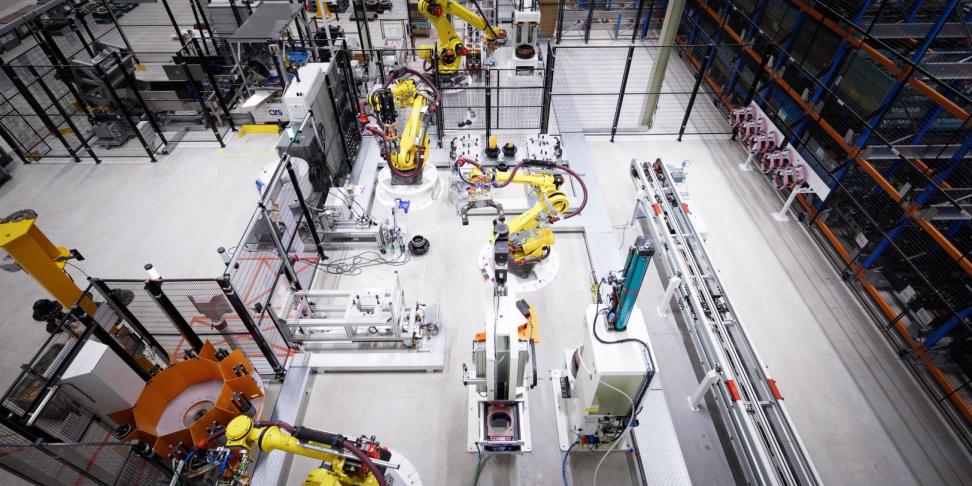

A virtual factory isn’t a buzzword or a fancy animation. It’s a complete digital twin of your production system: your robots, conveyors, tooling, human operators, and PLC logic. Running in a simulation environment that behaves like the real thing.

That means you can:

- Validate cycle times before commissioning

- Detect collisions, bottlenecks, and logic errors before they exist

- Train operators safely before the first part is produced

In practice, engineers use virtual factories to simulate robot programs, PLC safety logic, and human interactions before commissioning. That allows electrical and mechanical teams to validate their interfaces in parallel. Weeks before physical integration starts.

It’s not about replacing physical engineering. It’s about making sure your physical engineering succeeds the first time.

Think of it as a full-scale dress rehearsal for your factory - one that saves you from costly improvisation later.

The numbers speak for themselves

You don’t need to take it on faith. The data is clear.

30% faster time-to-market and 50% less rework with virtual commissioning

— Capgemini Smart Factory Report 2023

Up to 25% shorter engineering cycles when using digital twins

— Deloitte Digital Manufacturing Study 2023

ROI within 12–18 months when simulation is integrated early

— Siemens Industrial Edge, 2022

These numbers don’t come from theory. They come from companies that decided to stop guessing and start validating.

How to spot if you are in need of a virtual factory

If any of the following sound familiar, your next project should start with a virtual model:

- You’re managing more product variants than before and line balancing feels impossible.

- Your team is firefighting integration issues at the end of every project.

- You rely on supplier data you can’t fully verify until installation.

- You’re facing stricter ESG or machinery compliance demands.

- You can’t afford downtime, but your next system upgrade requires it.

These are not “complexity problems.” They’re visibility problems. And visibility is exactly what a virtual factory provides.

In the past, production challenges could be solved with experience and good engineering instinct. But with today’s connected, data-heavy systems eg. robotics, traceability, safety logic, and ESG reporting, the cost of learning by doing has exploded. What used to be a €50K redesign can now delay millions in production value.

At VDL Steelweld, precision starts long before production. By validating every design virtually, we deliver systems that are proven before they’re built. Reliable from day one.

The engineer’s case: how to convince management

Let’s face it, engineers see the value immediately, but management often needs a business case. Here’s how you can make it tangible:

Start with risk, not technology. Decision-makers understand risk. Show how virtual validation reduces the chance of late-stage failure; the single biggest budget and schedule killer.

Quantify delay cost. If one week of downtime equals €500,000 in lost output, shaving off six weeks of commissioning isn’t “nice-to-have”, it’s an ROI multiplier.

Link it to compliance. New regulations like the EU Machinery Regulation require traceable safety validation. Simulation provides the documentation trail automatically.

Position it as capability, not expense.

A virtual factory isn’t just software. It’s an internal capability that improves every future project. Once built, models can be reused, expanded, and standardised.

When you frame it that way, you’re not asking for a tool. You’re asking for resilience.

The hidden benefit: engineering confidence

Engineers are measured by reliability. And nothing builds confidence like knowing exactly how your system will behave before you commission it.

In a virtual environment, every decision, from robot placement to operator timing, is validated under realistic conditions. You can walk through the factory in 3D, test logic sequences, and show stakeholders live performance data.

Instead of saying “it should work,” you can say, “Here’s the proof.” That confidence doesn’t just make projects smoother. It changes the culture of engineering itself. Teams collaborate earlier. Errors surface faster. And innovation becomes less risky.

A practical example: what difference virtual factories make

One European truck assembly line recently transitioned to a fully virtual design process.

In the past, commissioning took 14 weeks. After implementing virtual simulation and testing robot logic in a digital twin, commissioning dropped to 8 weeks, with zero late-stage rework.

More importantly, the engineering team could demonstrate performance metrics — throughput, ergonomics, and energy use — to both the client and the safety authority before build. That level of predictability was unthinkable five years ago.

Why waiting is the biggest risk

If you think virtualisation is still “nice-to-have,” consider this: your competitors are already building digital maturity. Once they’ve modelled one line, every future line gets easier. That means: faster commissioning, cleaner validation, and data-driven improvement.

By the time you start, they’ll already be designing their next line from an established digital baseline.

In a market where margins, compliance, and capacity are under constant pressure, that’s not a small gap, it’s a strategic one.

The engineer’s takeaway

You don’t need to be a digital native to use virtual factories. You just need to be tired of surprises.

Virtual validation doesn’t replace your expertise, it amplifies it. It gives you data to defend your design decisions, evidence to justify investment, and confidence that your system will perform before a single robot moves.

The sooner you integrate simulation into your process, the sooner complexity becomes your competitive advantage.

Want to see how virtual validation could reduce your next project’s risk?

Book a meeting to discuss how a Virtual Factory could strengthen your next system design. Discover more at VDL Steelweld Virtual Factory Solutions